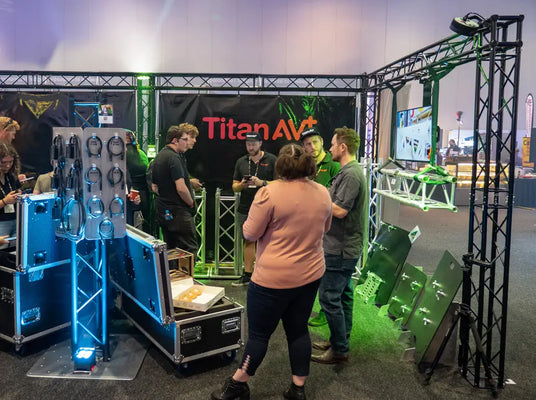

Titan AV Truss: What Makes It Different?

✅ NATA-Accredited Approved

Put through rigorous structural testing by a NATA-accredited authority (National Association of Testing Authorities) — Australia’s peak body for lab testing and accreditation. That means real science, verified data, and no offshore guesswork or self-certification.

✅ Government-Backed Innovation

Tested in partnership with AusIndustry and the University of Southern Queensland (USQ) to push engineering boundaries and raise safety standards.

✅ Independently Certified in Australia

To our knowledge, Titan AV is the only AV brand in Australia offering independently accredited truss testing on home soil.

✅ Material Tested. Grade Verified.

We use 6082-T6 Aluminium — stronger & more reliable than the 6061-T6 alloy used by many competitors.

✅ Engineered to Perform

From major events to permanent installations, Titan AV Truss is built to handle serious load, pressure, and repetition.

How Strong is Titan AV Truss? We Found Out.

Not all truss is created equal — and when you're suspending serious weight overhead, safety isn’t optional. That’s why we put Titan AV F34 lighting truss through the largest structural tests of their kind ever conducted in Australia, with engineers at the Centre for Future Materials pushing our truss to its absolute limits.

The result? Proven strength, reliability, and peace of mind when it matters most. Watch the full truss testing videos here ➔

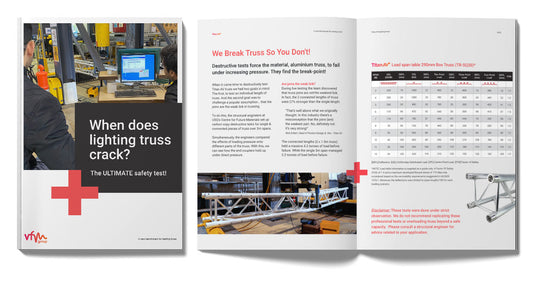

Titan AV Stage Truss Safety Report

Proof You Can Trust.

After rigorous independent testing by structural engineers at the University of Southern Queensland — with support from the Australian Government

— Titan AV Truss is backed by the most comprehensive truss testing ever conducted in Australia.

This wasn't just lab work. Engineers pushed our 290 box truss to the absolute limit to verify real-world performance under extreme loads. The result? Proven strength, reliability, and peace of mind — no guesswork, no shortcuts, no compromises.

Lighting Truss Basics

What is it? How do I use it? Where do I start? In our comprehensive Truss Buying Guide, you’ll learn the basics of lighting truss and how to choose the right stage truss for your needs.

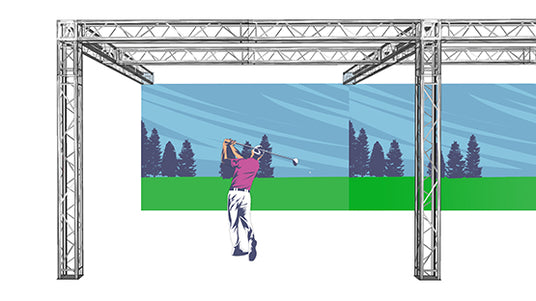

Tailor Your Truss Design with Expert Support

Got an idea for a truss structure? We're here to help you determine exactly how much truss you'll need to fit your space and meet your specific requirements. Whether you're starting fresh or refining an existing concept, our team is ready to assist in bringing your vision to life.

Note: For safety and structural integrity, we always recommend consulting a structural engineer when using lighting truss.

Colour Customisation For Lighting Truss

Need your truss to blend in or stand out? We handle the entire powder-coating process, offering a range of colours to match your design. Talk to our team about powder-coated truss!

Stage Truss Best Sellers

FAQs

What is Lighting Truss?

What is Lighting Truss?

Lighting truss, also known as stage truss, is a strong framework used to mount and support lighting and sound equipment. Truss is modular and dynamic. This means truss connects together (like giant LEGO®) to build changeable structures. Truss is typically constructed from aluminum or steel and comes in a variety of shapes and sizes.

You can learn more about the basics of trussing on our blog.

What size Lighting Truss do I need?

What size Lighting Truss do I need?

Choosing the right size of lighting truss is critical. The size of truss you choose will depend on the size and weight of the equipment you plan to mount, as well as the size of area you need to cover. Lightweight (100) trussing is for decorative displays and should not be used for rigging heavy equipment. Mid-weight (200) truss for retail, exhibition and small touring displays. With heavy-duty (290 & 400) truss made to rig large amounts of weighty AV equipment, indoors or outdoors.

The lighting truss numbers refer to measurements. For example, 290 truss is 290mm x 290mm from the outside of each large tube that defines its shape, known as chords. The higher the number, the bigger the lighting truss, the more heavy-duty its application. If you are unsure what size you need, give us a call for a chat about your unique needs.

What types of Stage Truss are available?

What types of Stage Truss are available?

There are many different shapes of lighting truss available, including flat, triangular, box (or square truss), and 5 chord truss. Each type of truss offers its own advantages and can be used for a variety of applications.

Different shapes of truss can also be used together. Tube and flat truss make great additional supports and mounts to rig off for larger tri or box truss structures.

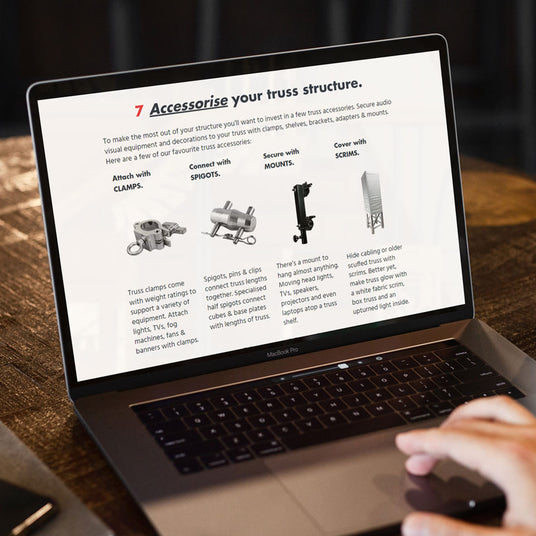

Which Lighting Truss accessories do I need?

Which Lighting Truss accessories do I need?

When it comes to lighting truss, there are a few accessories you should consider to maximize the truss's potential. The most important accessories include clamps, spigots, shelves, brackets, base plates, adapters and mounts. Clamps are used to secure gear to the truss, while spigots (or connectors) are used to join multiple pieces of truss. Truss scrims are made of lightweight fabric and can be used to hide unsightly wires, or to create special effects with lighting. Lastly, truss base plates provide stability and support to your structure.

It’s important to note that truss accessories are fit for 50mm (290 & 400) or 32mm (200) truss. These measurements refer to the diameter of the main chords (largest tubes on the truss). They will ensure that you match the right sized clamp, spigot or mount for your size of truss. For example, 290 truss has 50mm chords requiring 50mm accessories.

What is powder coated Truss?

What is powder coated Truss?

Powder coated truss allows you to change the colour of your trussing. Adding a custom colour powder coat to truss is an effective way to stand out, stay hidden or be creative. Theatres and convention centre's often powder coat truss to blend installations into the ceiling or backdrop out of sight.

The powder coating applies as a free-flowing dry powder, then cured under heat. It provides a stronger finish and is more resistant than paint. Because powder coating covers the truss, it's thus possible to scratch off. This is why powder coated truss is ideal for applications that need little to no transportation.

How do I build structures with Lighting Truss?

How do I build structures with Lighting Truss?

Building a structure from lighting truss can be a fun and creative process. Anyone can assemble small truss structures all you need is a hammer and a little muscle. To make things simple trussing is genderless, meaning it will connect at either end with precise alignment. Head over to our blog to watch us assemble a basic box truss arch.

How much weight can Stage Truss hold?

How much weight can Stage Truss hold?

The amount of weight a lighting truss can safely hold will depend on its size, material, and construction. Generally, trusses are designed to hold up to a certain weight capacity, so it is important to check with the manufacturer's specifications to ensure it can safely support the weight of the lights you plan to hang from it. Additional factors like high winds, storms and unstable ground conditions should also be taken into account.

Note: Large-scale truss structures may need specialised load shifting equipment, such as chain motors, chest harnesses and arresting shock absorber lines, to safely erect the aluminium truss. You should always consult a structural engineer for advice related to your application.

Is Titan AV Lighting Truss independently safety tested?

Is Titan AV Lighting Truss independently safety tested?

Yes, Titan AV truss is independently tested and certified in Australia to meet the highest safety standards. This is important because not all lighting truss are created equal! Differences in welding, manufacturing and raw materials can make or literally break truss. Lighting truss structures often hold hundreds, if not thousands, of kilos above patrons. With this type of risk, it’s critical to know with 100% assurance that it's safe to use.

We are committed to providing the highest quality products and services to our customers, which is why we have our trusses tested by a third-party laboratory to ensure our aluminium truss meet industry standards. You can learn more about Titan AV truss safety tests on our blog. If you have any questions about the testing process, please don't hesitate to reach out. We're here to help!